As much as it’s vitally important you receive clean water, it’s just as crucial that used water is removed from your property safely and responsibly. But what exactly happens when we flush the chain, run the tap or use the washing machine? In short, this now ‘wastewater’ needs to be returned back to rivers where it first came from. We’re going to explain the processes and treatment it needs to go through in order to be returned back into the cycle…

1) Removing the wastewater

The second you pull the plug or flush the chain, the wastewater is carried down the drain that leads to a pipe. This pipe then connects to a sewer pipe (an even larger one!) that runs hidden beneath the roads. This sewer runs into a network of other sewers that carries the wastewater to a sewage treatment works where it begins its journey of many cleaning processes.

2) Screening (also known as pre-treatment)

This next stage involves cleaning waste water and riding it of any large items, including those that shouldn’t be there, and from our previous article, I think we know there can be quite a few! Grit is also commonly found amongst the wastewater, so that also needs to be sieved out.

3) Primary treatment

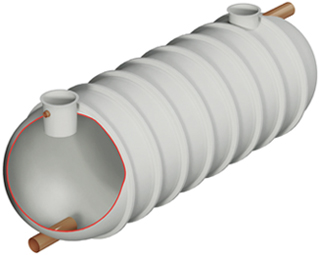

At this point, the water still contains solid matter. This needs to be separated by putting the wastewater into settlement tanks which encourages the solids to sink to the bottom and collect as ‘sludge’. The remaining water is then passed over a wall towards the top of the tank, so it can be carried on to the next treatment.

4) Secondary treatment

With the ‘sludge’ now removed, this stage of treatment focuses on those unseen bugs that live in the wastewater. At large sewage treatment works, the water is passed into rectangular shaped tanks known as ‘aeration lanes’. Air is pumped into the tank which causes the bugs to break down as the good bacteria eats them! The more this happens, the more the good bacteria multiplies and takes over.

5) Final settlement

Wastewater is then passed through to a final settlement tank. The purpose of this is to allow the remaining good bacteria to settle to the bottom, creating another sludge that can then be recycled and sent back to the secondary treatment stage. The rest of it will then pass over another wall and on to the next stage of the cycle; the sludge treatment. If the river the water is returning to is especially sensitive, further treatment will be carried out at this point so the finer particles are also filtered out.

6) Sludge Treatment

This penultimate stage revisits the sludge that is produced at stage 3. The sludge is now collected and the majority of it is recycled for agricultural purposes (fertiliser) while the rest of it can be used to create energy through numerous different methods (combined heat and power, gas to grid and thermal destruction).

7) Back to the river

Finally, the wastewater is clean! This means it can be returned to the rivers and streams in the local areas. The quality and cleanliness of the water is regulated by the Environment Agency to ensure it meets the necessary high standards.

So, now you know the journey your wastewater goes through as soon as you pull the plug! Wildon (UK) Ltd If you’re in need of sewage treatment work, then please get in touch with the drainage specialists here at Wildon (UK) Ltd. Whether it’s domestic or commercial, our team can see to your problem and fix it fast, so you aren’t left with any mess! Simply give us a call today and we’ll be more than happy to help.

Go back to