Slurry is a substance which is commonly employed in numerous industries including agriculture. Without this product, many of the modern amenities which we enjoy would simply not exist. While the benefits are numerous, so are the risks to an untrained worker. In fact, grievous injuries and death occur each year as a result of improper safety management. At Wildon UK, we take the safety of every worker quite seriously. It is therefore critical that we explore some of the recommended procedures when handling this substance.

Initial Steps

Before physically handling the slurry, it is important to always adhere to a few key steps. These include:

- Allow for proper ventilation inside of the building by opening all doors and windows. It is preferable to mix the product outside if possible.

- Make certain that all animals are safely removed from the work area.

- Make certain no children are present and close all apertures that are large enough to accommodate a human body.

Adhering to these preliminary steps will cut down on a massive amount of risks that would otherwise be present.

The Importance of a Self-Contained Breathing Apparatus

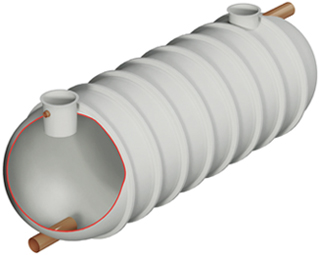

One of the primary dangers of slurry is the fact that when it is stored within a tank (or any enclosed area), a buildup of toxic and deadly gases will occur. These gases include:

- Methane

- Ammonia

- Carbon dioxide

- Hydrogen sulfide

Note that ALL of these gases can cause death. High concentrations of methane can lead to an explosion but by far, the most dangerous of these four is hydrogen sulfide. This gas cannot be smelled and within seconds, it can lead to unconsciousness and death. Thus, several safety measures need to be taken. One needs to wear an apparatus with its own air supply (normal filters will NOT work). A harness and lifeline should be attached to the exterior of the tank and more than one person should always be present.

Finally, noxious gas detectors should also be a part of one’s personal protective equipment (PPE). These units will give advanced warnings of potentially dangerous concentrations. This is particularly important during the mixing phase, as gases will normally be liberated from the mixture. Always assume that these gases are present.

Mechanical Concerns

All equipment should be maintained in working order and if a fault is suspected, it should not be used and this should be reported to a supervisor. Some concerns can be seen as:

- Standing within close proximity to the pump and exhaust while it is operation.

- Making certain that PTO (Power Take-Off) shafts are guarded.

- Driving carefully when fields are sloped or uneven to prevent the vehicle from overturning.

Additional Concerns

Notwithstanding these main priorities, there are other concerns that should be taken just as seriously. Open flames can never be present due to the possibility of methane gas. Working on a windy day is preferable if possible. Two-way radios are an added benefit (as long as they are rated for such usage). Avoid entering the building once the mixer has started for a minimum of thirty minutes.

Wildon UK

All of these recommendations need to be taken seriously and always used in synergy with one another. While we are proud to supply a wide variety of slurry pumps, Wildon UK is just as concerned that all of our clients are working in a safe and secure environment. Should you have any additional questions, please do not hesitate to contact us directly for further information.

Go back to