Toxic gases and a lethal risk

Slurry work, an essential farming activity, poses many risks and can be highly dangerous. The two major hazards are the risk of asphyxiation (gas poisoning) when high concentrations of toxic slurry gases are released, and the risk of drowning in slurry. After two wet seasons, which have restricted spreading, plenty of slurry still remains in store.

‘14% of all farm deaths’

During the period 2000-2009, death by asphyxiation (gas poisoning) and drowning in slurry accounted for 14% of all farm deaths. The risk of drowning in slurry seems to be statistically greater than the risk of asphyxiation, though these factors are often interlinked when fatal accidents occur. For example, between 2000 and 2010, drowning in slurry or water was responsible for 30% of child deaths on farms, and also 8% of all deaths involving elderly farm workers.

Bacterial activity occurs in slurry tanks. This process releases a cocktail of toxic gases such as carbon dioxide, hydrogen sulphide and ammonia. All are highly dangerous, but hydrogen sulphide, the most lethal, is odourless at higher concentration levels. Exposure to hydrogen sulphide gas causes eye and respiratory tract irritation at concentrations of just 20 atmospheric parts per million (ppm), and disorientation, nausea and collapse above 500ppm, which is a common reading in livestock enclosures.

Slurry pump agitation & trapped gases

Studies show the greatest risk occurs during slurry pump agitation when the trapped gases are released by mixing. Gas concentration is highest just after mixing begins or when mixing in cold weather, in still air, or in a confined space. Deep tanks also present a high risk, as does slurry stored over many months or the addition of silage effluent to the slurry mix.

Such evidence points to a continuing need for strict safe working practices wherever slurry work is carried out to prevent tragic incidents. Obviously all animals and people, other than essential slurry operators, should be kept away. Maximum ventilation of working areas would also seem a key precaution. Wherever possible slurry pump agitation should be controlled from outside of the building, otherwise operators must leave immediately pumping starts. No return to the area should be allowed for 30 minutes – even longer if the tank is large.

Slurry safety

To keep slurry operators safe, there should be a minimum of two workers present at all times. The tank area should only be entered when absolutely necessary. On such occasions a harness connected to two outside workers, and breathing apparatus with an independent air supply, must always be used. Health and Safety Executive guidelines cover such instances and should be scrupulously followed.

Drowning is an ever present hazard on farms especially where water is accessible to children. Every effort should be made to fence off water tanks and make ponds, river and lake areas as safe as possible. Any open and accessible slurry tank should be walled off to at least 1.8 metres in height and fitted with locked gates.

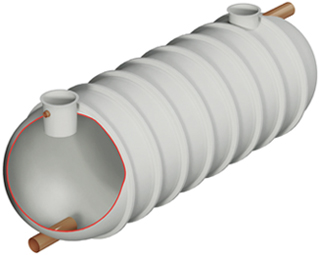

Slurry tanks, pits, and surrounding areas should be carefully designed to support safe working practices. A dedicated access platform with safety rails assists safe tank emptying and all manhole openings should be covered and protected. Safety risks also arise with outdoor lagoons where scrape holes need adequate protection. Any pits below ground level must be covered when not in use. Remember that any cover should be designed to take not only the weight of humans, but also animals and vehicles.

Go back to