Water is a precious resource and one which is scarce in many areas of the world. This applies to arid countries which often experience droughts, and in areas where demand is high, resulting in shortages. A pioneering solution is to thoroughly process wastewater to turn it back into safe, drinkable water. This is a highly effective system which creates valuable drinkable water in water-short places, reduces needless waste and all whilst costing less than alternatives, like desalinating seawater.

Whilst you may think such useful technology would be widespread, there has been one major stumbling block: public opinion. Simply, people don’t like the idea of drinking what has previously been wastewater. This is despite the fact that the treatment process is exceptionally thorough, often creating water cleaner than the average drinking water. The key to improving the public’s perception of processing wastewater into drinking water is education. To this end, in this article we’ll look at how wastewater is turned into perfectly clean, drinkable water.

The filtering process

Wastewater treatment

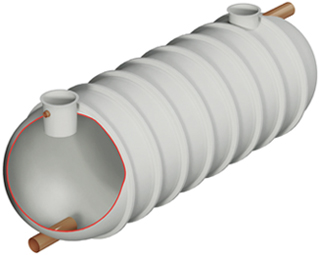

First of all, wastewater undergoes the standard treatment process. In this procedure, solids and large particles are filtered out through sedimentation tanks. Helpful bacteria are then added to the water to consume the remaining small organic solids. The water is then finely filtered, disinfected and desalinated.

Recycled water

If the recycled water is intended for human consumption, the next stage is to put it through further treatment before mixing it with natural water supplies. However, sewage water which has gone through wastewater treatment forms ‘recycled water’ which is clean enough for some agricultural and industrial usage.

Drinking water treatment

The recycled water next undergoes advanced water treatment processes to make it fit for human consumption. Firstly, the water goes through microfiltration to remove even the smallest solids. The next phase involves reverse osmosis whereby water is put under pressure to pass through a membrane. This membrane filters out undesirable components such as bacteria, viruses and pharmaceuticals. The water is then disinfected using special chemicals and strong UV light.

Indirect potable water

The treated water is then usually added to a reservoir or pumped into underground aquifers, combining it with natural water supplies. This makes it ‘indirect potable water’: recycled water which is treated to become drinkable and is then added to and mixed with natural water – such as groundwater – before becoming drinking water.

Arguably, the main benefit of this stage – mixing the treated water with natural water supplies – is that it helps improve public perception of drinking recycled wastewater. The dilution of treated wastewater in a natural water source isn’t crucial and some systems skip this stage without negative side effects.

The final step is the treated water/natural water mix undergoing standard water purification processes.

Indirect potable water is entirely safe to drink and places across the world without easy access to fresh water already use such processes. Areas in Australia, Singapore, southern states of America – like California and Texas – and Namibia all make use of wastewater recycling facilities to help provide their population’s drinking water.

Wildon UK is an expert in wastewater treatment and drainage solutions, operating across Stoke on Trent, Staffordshire and further afield across the UK. Our specialist engineers are highly trained and have the expertise to deal with a wide range of drainage and wastewater issues, across domestic, commercial and agricultural premises. For professional advice regarding wastewater systems, maintenance, repairs, and more, contact our helpful team today.

Go back to